CORROSION RESEARCH CENTER

High Resolution Techniques

Related

Images

|

CORROSION RESEARCH CENTER

|

|

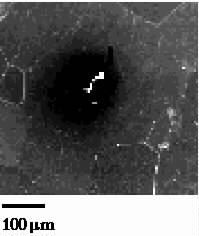

FIGURE 1b

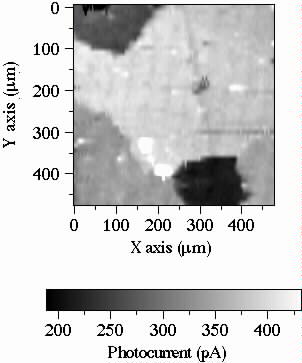

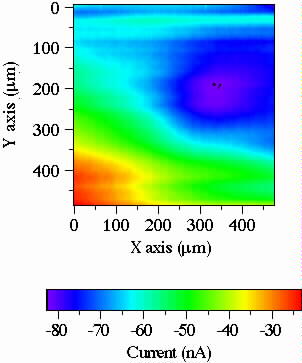

FIGURE 1c

FIGURE 1. SEM, PEM, and SECM of

the same

area in

a large grain Ti sample containing an inclusion (Al-Si particle). Notice the inclusions

appearing as a dark area inside the grain shown in the PEM image (1b) and then shown as a

region of high electrochemical activity in the SECM test (1c). The PEM image was done in

a 0.05 M H2SO4 solution, the Ti electrode was polarized at

+1.5 VSCE (the total current measured in the Ti electrode was 48 nA). The

SECM image was obtained by using a 0.1 M K4Fe(CN)6

solution, the Ti electrode was biased at 1 VSCE (the total current measured in

the Ti electrode was 8 µA), whereas the Gold part of the microelectrode was biased

to 0 VSCE (the background current measured in the microelectrode in this

solution prior to biasing the Ti electrode was 120 pA).

SECM (no feed-back)

FIGURE 2a

Topography (with feed-back)

FIGURE 2b

SECM (with feed-back)

FIGURE 2c

FIGURE 2. SECM and Topography (squares of 35 µm by side) for a Pt microelectrode imbedded in glass. The sample and the microelectrode probe were immersed in 0.1 M K4Fe(CN)6 solution. The SECM without feedback was obtained at an approximate distance between the sample and the probe Z Å 4 µm. The SECM image obtained simultaneously with the shear-force topography (in liquid) was obtained by moving the probe at about z < 50 nm.

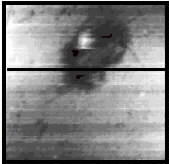

No Feedback PEM

FIGURE 3b

Topography Liquid (PEM)

FIGURE 3c

PEM with Feedback

FIGURE 3d

FIGURE 3. PEM and topography (squares of 30 µm by side) for polycrystalline titanium. The sample and the optical fiber ultra-microelectrode were immersed in 0.05 M H2SO4 solution. The PEM image obtained simultaneously with the shear-force topography (in liquid) was obtained by moving the probe at about Z < 50 nm.

CRC AREAS OF RESEARCH